Ridgid EB4424 Support Question

Find answers below for this question about Ridgid EB4424.Need a Ridgid EB4424 manual? We have 1 online manual for this item!

Question posted by evace109 on December 16th, 2015

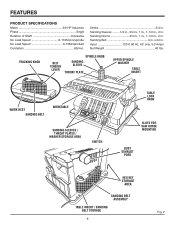

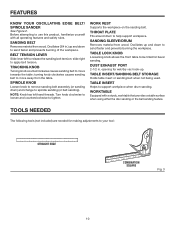

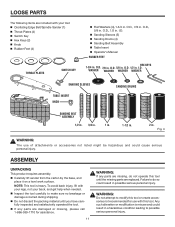

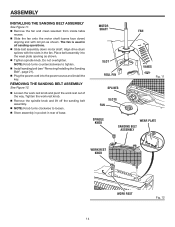

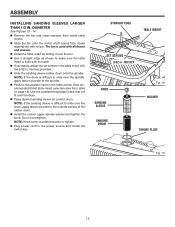

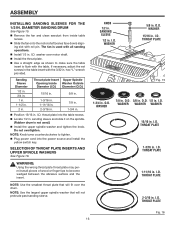

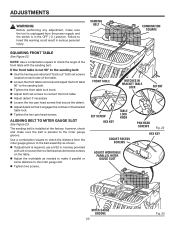

Rigid Spindle Sander Manual Changing The Belt To A Simple Spindle Sander.

Can't seem to locate my manual and want to change the belt configuration to a simple single spindle device but for the life of me I can't figure out how to do it. A U Tube demo would help but maybe you guys can explain verbally the steps needed to make this change.

Current Answers

Answer #1: Posted by TechSupport101 on December 17th, 2015 7:00 AM

Hi. The Owners Manual is available here https://www.helpowl.com/manuals/Ridgid/EB4424/182578

Related Ridgid EB4424 Manual Pages

Similar Questions

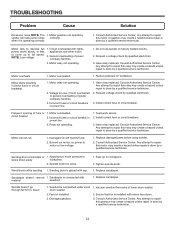

Spindle Will Not Move Began To Smoke

anything I can do or take to s

anything I can do or take to s

(Posted by ferrellandcelest 2 years ago)

How To Replace Drive Roller In Ridgid R2740 Belt Sander

How to replace drive roller in ridgid r2740 belt sander. I have the sander disassembled but cannot f...

How to replace drive roller in ridgid r2740 belt sander. I have the sander disassembled but cannot f...

(Posted by Jerrydee49071 3 years ago)

Where Can I Purchase A Spindle Knob For The Rigid Belt Sander For Eb 44242

(Posted by johncrausen 10 years ago)