Pfaff hobbylock 796 Support Question

Find answers below for this question about Pfaff hobbylock 796.Need a Pfaff hobbylock 796 manual? We have 1 online manual for this item!

Question posted by Rosemcmahon48 on April 17th, 2023

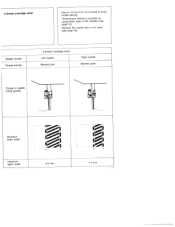

Upper Knife Knob

Current Answers

Answer #1: Posted by SonuKumar on April 17th, 2023 9:02 PM

- Locate the knob and the corresponding post on the machine where it attaches.

- Align the knob with the post on the machine.

- Push the knob onto the post and turn it clockwise until it is secure.

If the knob is not aligning properly or is difficult to turn, you may need to adjust the position of the knife manually. To do this:

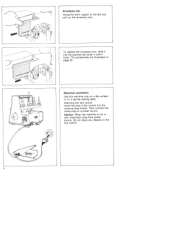

- Turn off the machine and unplug it from the power source.

- Open the front cover of the machine to access the knife.

- Gently move the knife to the desired position with your fingers.

- Close the front cover of the machine and plug it back in.

- Test the machine to ensure that the knife is in the correct position and the knob is secure.

If you are still having difficulty getting the knob back on or adjusting the knife position, it may be best to contact a qualified sewing machine technician for assistance. They will have the expertise to diagnose and repair any issues with your serger.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by MarkivShah on April 17th, 2023 11:50 PM

- Make sure the upper knife is in the correct position for your sewing project.

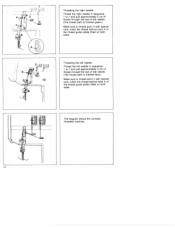

- Hold the knob in your hand with the screw pointing up.

- Locate the screw hole on the top of the upper knife assembly.

- Carefully line up the screw hole on the knob with the screw hole on the upper knife assembly.

- Slowly begin to thread the screw into the hole, making sure to keep the knob and upper knife aligned.

- Once the screw is partially threaded, adjust the position of the upper knife if needed.

- Tighten the screw completely, making sure not to over-tighten it.

If you're still having trouble getting the knob back on, you might want to consult the manual for your specific sewing machine model or contact the manufacturer for assistance.

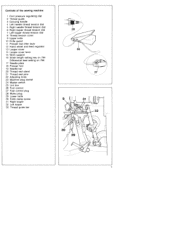

Related Pfaff hobbylock 796 Manual Pages

Similar Questions

How does the Edge Guide work for the Pfaff Select 1540 sewing machine?

I have replaced the upper blade in the serger hobby lock 796 I can't return the blade to the proper ...

I have rethreaded as per diagrams but its still not sewing. l think its bcz the left needle is jamme...

I have a pfaff 259. When I push on the foot petal the motor runs but the machine itself doesn't run....

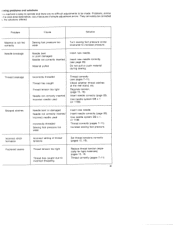

Do I need a new upper or lower knife or is it another problem