Makita LS1216L Support Question

Find answers below for this question about Makita LS1216L.Need a Makita LS1216L manual? We have 4 online manuals for this item!

Question posted by janlensing on March 4th, 2014

How Do I Adjust The Laser Line Its Off The Cut

The person who posted this question about this Makita product did not include a detailed explanation. Please use the "Request More Information" button to the right if more details would help you to answer this question.

Current Answers

Answer #1: Posted by freginold on May 17th, 2014 6:18 PM

Hi, the instructions for adjusting the laser line can be found on page 11 of the manual. If you need a copy of the manual, you can download it here:

http://www.makita.com.hk/catalog/images/products/LS12162.pdf

http://www.makita.com.hk/catalog/images/products/LS12162.pdf

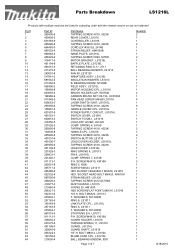

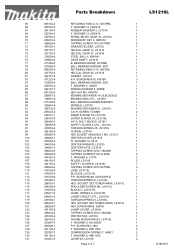

Related Makita LS1216L Manual Pages

Similar Questions

How To Adjust Carburetor Speed On Makita G 1100

Engine running too fast, how do I adjust the speed?

Engine running too fast, how do I adjust the speed?

(Posted by sacourville 9 years ago)

How Do I Adjust The Miter Bed To Zero?

I have adjusted the fence as much as I can and the cut at zore is still off by 1/16th to 3/32nds whe...

I have adjusted the fence as much as I can and the cut at zore is still off by 1/16th to 3/32nds whe...

(Posted by CalvinOcker 9 years ago)

Blue Blade Protector

Blade cover wont retract when i pull handle down to cut . Saw was dropped and I think some sort of l...

Blade cover wont retract when i pull handle down to cut . Saw was dropped and I think some sort of l...

(Posted by spvremodeling 9 years ago)