Dewalt D55168 Support Question

Find answers below for this question about Dewalt D55168.Need a Dewalt D55168 manual? We have 4 online manuals for this item!

Question posted by mrdemott on November 1st, 2021

Won't Transfer The Air In The Tank To The Hose.

Current Answers

Answer #1: Posted by SonuKumar on November 1st, 2021 8:14 AM

https://www.youtube.com/watch?v=l05f2rkRQnQ

https://www.youtube.com/watch?v=bu9cZWULPkU

https://www.manualslib.com/products/Dewalt-D55168-533070.html

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Answer #2: Posted by Technoprince123 on November 1st, 2021 10:06 AM

http://powertool.manualsonline.com/manuals/mfg/dewalt/d55168_1.html

https://manualzz.com/doc/en/1980348/dewalt-d55168-type-1-air-compressor-owner-s-manual

Please response if this answer is acceptable and solw your problem thanks

Related Dewalt D55168 Manual Pages

Similar Questions

Looking for a part that the knob screws on to the regulator, not the kit.

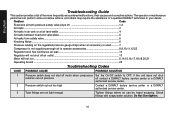

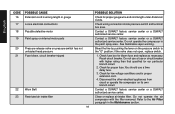

compressor won't build pressure. I have replaced the manifold and it will only go to about 40 psi. I...

builds tp 20 psi and stops and continues running