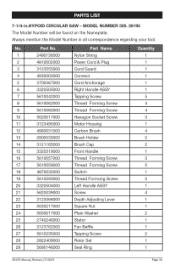

Craftsman 28195 Support Question

Find answers below for this question about Craftsman 28195 - Professional 7-1/4 Hypoid Saw.Need a Craftsman 28195 manual? We have 1 online manual for this item!

Question posted by jabutler470 on November 13th, 2023

The Stud That The Height Adjustment Lever Goes On Is Striped. Replaceable Or Wh

Current Answers

Answer #1: Posted by SonuKumar on November 13th, 2023 10:12 PM

To replace the stud, you will need to remove the height adjustment lever and then remove the stud from the machine. Once the stud is removed, you can replace it with a new one.

Here are the steps on how to replace the stud:

Remove the height adjustment lever. To do this, you will need to loosen the two screws that hold it in place. Once the screws are loose, you can carefully pry the lever off of the machine.

Remove the stud. To do this, you will need to use a stud extractor. A stud extractor is a tool that is designed to remove stripped studs. To use a stud extractor, you will need to attach it to the stud and then turn it counter-clockwise. The stud extractor will apply pressure to the stud and it will eventually break free.

Install the new stud. To do this, you will need to thread the new stud into the hole where the old stud was located. Once the stud is threaded in, you can tighten it down with a wrench.

Reinstall the height adjustment lever. To do this, you will need to carefully position the lever on the machine and then tighten the two screws that hold it in place.

Once you have completed these steps, you will have replaced the stripped stud and your machine will be working properly again.

Please respond to my effort to provide you with the best possible solution by using the "Acceptable Solution" and/or the "Helpful" buttons when the answer has proven to be helpful.

Regards,

Sonu

Your search handyman for all e-support needs!!

Related Craftsman 28195 Manual Pages

Similar Questions

Are replacement brushes available for craftsman 320-26302 drill? Can't even find a part number.

Can I purchase a replacement battery for a craftsman compressor / inflator model 75116?

I, just purchased this new plunge Router less than 1 year ago, it has been used about 10 times on li...

Can the battery be replaced on the Craftsman 4.8 volt pistol screwdriver. I've had mine 18 months an...